X-Ray Analysis Services

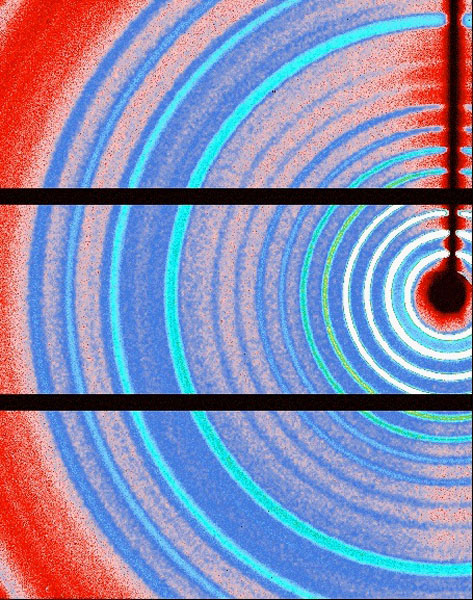

Small angle x-ray scattering from a long-chain silver-based acid structure. Well defined diffraction rings can be used to determine the long spacing of the structure. The ratio between the position of the rings can be used to determine the symmetry of the structure in nanostructures including biological materials. |

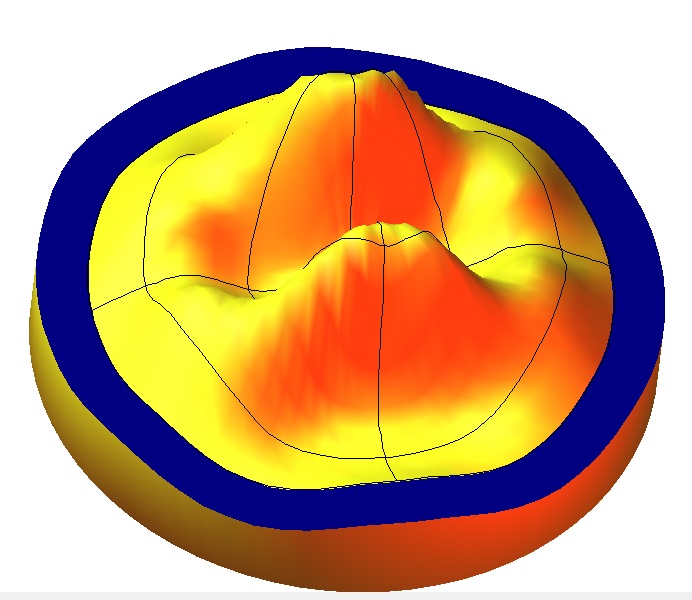

Pole figure texture graph from a rolled metal sheet using x-ray diffraction. Texture analysis can be used to determine the relative distribution of grain orientations in the structure, which have been shown to have a strong impact in the mechanic, thermal and electronic properties of materials. |

Prairie Nanotechnology offers a wide variety of x-ray analysis services for materials characterization, covering a wide variety of applications and industries.

|

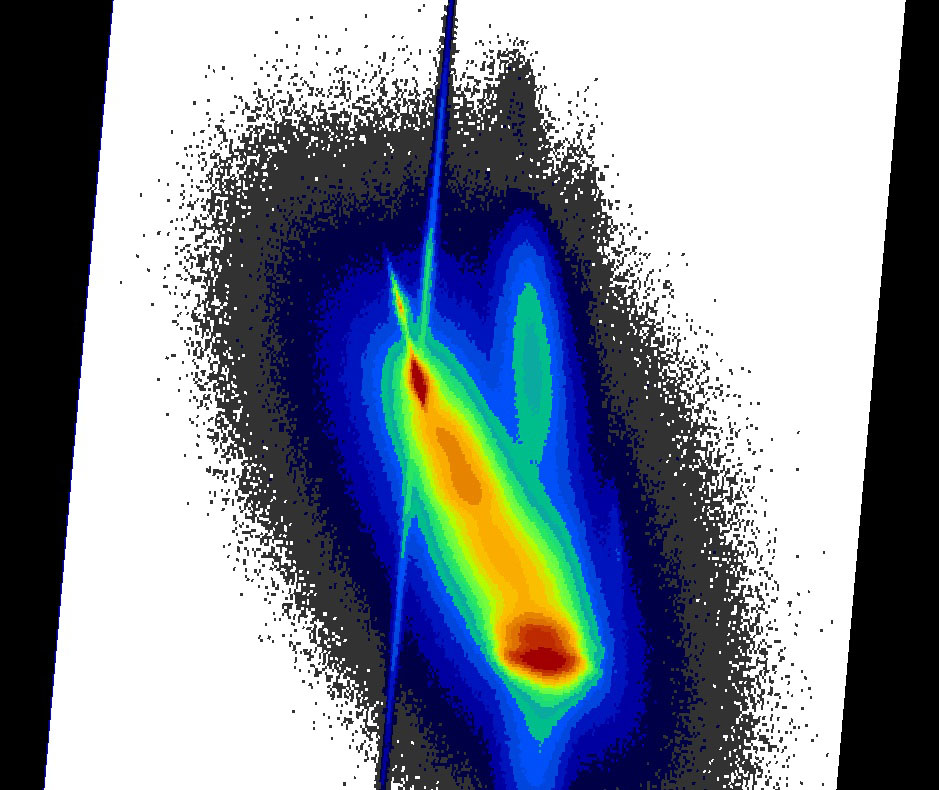

High-resolution x-ray diffraction reciprocal space mapping from a multilayer semiconductor structure on Si substrate typically used in high-speed microelectronic devices. A strained Si thin film was deposited on top of a relaxed SiGe alloy thick layer with composition variation. The relative position of the diffraction spots can be used to accurately determine the composition and strain status of each individual layer. |

Contact us to discuss your characterization needs.

Home || Industry Support || Research Support || Education Support || Contact

Atomic Force Microscopy || X-Ray Analysis || Scanning Electron Microscopy

Prairie Nanotechnology, 60 Hazelwood Drive, Champaign, IL 61820

Phone: 708-406-9608, Fax: 815-301-3851

Email us at: info@prairienanotech.com

This website and its contents © 2015 Prairie Nanotechnology, LLC. All Rights Reserved.